|

Multiple Disinfectant Barriers Within A Multiple Barrier System:

A New Drinking Water Paradigm for Public Health Protection.

Abstract

For well over 100 years in the U.S. the multiple barrier approach has been used to provide potable water that insures

public health protection has been. These multiple barrier included protected upland watersheds and/or well head

protection areas; proven drinking water treatment practices to remove particulates where needed; a large clearwell to

provide adequate contact time for chlorine and the maintenance of a distribution system disinfectant residual. This

paper demonstrates that many things have change including the loss of watershed protection areas; increased

concern over the carcinogenicity and reproductive health effects of chemical disinfectant by-products; emergence of

pathogens that are more resistant to chemical disinfectants; and a population goring more vulnerable to morbidity

and mortality from waterborne diseases. As a result, it is time for a new drinking water paradigm for public health

protection involving multiple disinfectant barriers with this historical multiple barrier approach. The paper presents

the public health and economic benefits of using a combination of disinfectants in a drinking water treatment

strategy. Two case studies are presented: Ultraviolet disinfection followed by chlorination; and ozonation followed by Ultraviolet

disinfection and then chlorination

Keywords

Multiple disinfection barriers; synergistic disinfection; Ultraviolet; ozone; chlorine; Giardia; Cryptosporidium, Adenovirus

Introduction

For well over a century the United States has used a multiple (four) barrier approach to protect

public health from waterborne diseases. The first barrier included watershed and/or wellhead

protection. However, in the past three decades, watershed and wellhead protection has been

eroded in many areas due to growing population densities and the publicís desire for waterfront

property and recreational use of drinking water reservoirs. The economic value of waterfront

real estate has led many public and private drinking water utilities to sell large parts of their

protected watersheds for housing developments. Similarly, mandatory set back distances for

certain types of developments from wellhead protection areas have been relaxed in many parts of

the U.S.

The second barrier has always been appropriate treatment to take care of tastes, odor and color of

the water as well as remove items that might interfere with disinfection such as particles or

chlorine demanding substances. These treatment technologies have received increased

optimization in the past thirty years but many treatment plants continue to face challenges from

rapid changes in raw water quality as well as declining budgets for needed repairs and upgrades.

The third barrier has long been primary disinfection using chlorine. However, since 1972 the use

of chlorine has raised concerns due to the production of disinfection by-products (DBPs). These

by-products including the trihalomethanes, the haloacetic acids and several others have long

been a concern due to their potential carcinogenicity. More recently, concerns over the role of

DBPs, in particular bromodichloromethane, in reproductive health effects including miscarriages

have sparked strong public reaction and significant lawsuits. In contrast, the emergence of

pathogenic Giardia lamblia cysts as a waterborne disease causing agent required higher chlorine

doses, and hence more potential for DBPs, for effective disinfection. Further, since 1993.

Milwaukee outbreak Cryptosporidium parvum oocysts have been the leading pathogen of

concern in U.S. drinking water and chlorine is ineffective for disinfection of oocysts. In

response to these changes, many utilities switched to ozone as their primary disinfectant. Ozone

has been a successful option for many water systems and can be provide other benefits including

taste and odor control and improved particle removal in filtration. However, ozone as with all

disinfectants has negative aspects as well including production of the DBP bromate which can

result in significant health effects. In addition, ozone is a more costly and complex disinfection

system than utilities were accustomed to with chlorination. More recently, it has been shown

that ozone doses required for inactivation of Cryptosporidium oocysts in colder waters (e.g., 1

0C) are much higher, maybe by as much as a factor of 2.0, than was first thought. If this

temperature effect is the result of mass transfer phenomena then similar results may also be

found for other chemical disinfectants or for the disinfection requirements of Giardia cysts.

Concerns with chlorine and ozone coupled with the emergence of Ultraviolet disinfection for drinking

water in 1998 have led many utilities to examine using Ultraviolet light as their primary disinfectant.

Ultraviolet has many advantages including lower costs and operational simplicity relative to ozone. Ultraviolet

light is highly effective for Giardia and Cryptosporidium and Ultraviolet light at typical doses used for

disinfection (40 to 70 mJ/cm2) does not contribute to the regulated disinfection by-product

concerns. However, Ultraviolet disinfection is also not a panacea since waterborne pathogens such as

Adenovirus are rather resistant to Ultraviolet light. In addition, implementation of Ultraviolet disinfection of

drinking water on a large scale is a new experience for the U.S. Therefore, effective approaches

for the selection, design, operation and monitoring of Ultraviolet disinfection systems must be proven.

The fourth barrier has always been a secondary disinfectant, typically chlorine, to maintain a

distribution system disinfectant residual. However, many systems have converted from free

chlorine residual to a combined chlorine or monochloramine residual since it helps control DBP

formation and persists longer in the distribution system. The use of chloramination for

secondary disinfection is well proven but does require more careful control and in some systems

steps are needed to prevent nitrification.

In addition to the changing paradigms in U.S. public health protection, the drinking water

regulations are also changing to address these emerging concerns. The United States

Environmental Protection Agency (USEPA) is currently in the process of developing the Long

Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) and the Stage 2 Disinfectants

and Disinfection Byproducts Rule (DBPR). These rules, to be finalized in 2004 and

implemented over the next five years will encourage drinking water utilities to find a balance

between the risks of pathogenic microorganisms and disinfection byproducts. The LT2ESWTR

details drinking water regulations for public water systems using surface waters or groundwater

under the influence of surface water as sources. The purpose of these rules is to provide the

public adequate protection against microbial pathogens. The rules will focus on waterborne

pathogens including Giardia, Cryptosporidium and human enteric viruses. The DBPR is

intended to aid in the reduction of disinfection byproducts formed during chemical disinfection

with chlorine. These rules will further limit the allowable levels of trihalomethanes (THMís)

and haloacetic acids (HAAís) to 80 ug/L and 60 ug/L, respectively and require the monitoring of

distribution system water quality for DBPs based on locational running annual averages (LRAA)

to insure a more uniform decrease in DBPS throughout a communities water system

(www.epa.gov, 2003).

With so many new challenges to the multiple barrier approach to drinking water treatment and

with the realization that there must be a balance between microbial health effects and chemical or DBP health effects it is clear that no single disinfectant can meet most drinking water systemís

needs. Therefore, it is time for a new paradigm to protect public health from waterborne disease

- the use of multiple disinfectant barriers within the historical multiple barrier approach.

This paper will document the implementation of multiple disinfectants at several systems in the

U.S. and the resultant public health and economic significance of those changes.

Multiple Disinfectant Barrier Case Studies

Case studies are based on numerous lessons learned from recent experiences in the U.S. but no

single case study is directly related to an actual U.S. drinking water system in order to protect the

privacy and the legal rights and responsibilities of U.S. public drinking water utilities. All cases

will be examined from three standpoints: a) compliance with Giardia, Cryptosporidium and virus

regulations; b) compliance with DBP regulations; and c) costs.

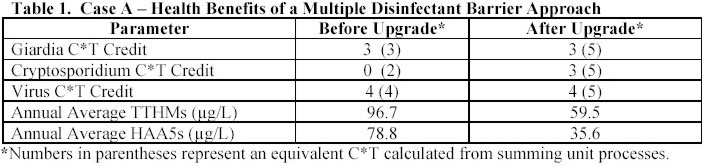

Case A - Conventional Treatment with Ozone/Ultraviolet Disinfection and Chlorine Residual

Case A involves a 15 MGD (2,366 m3/hr) conventional treatment facility that had used chlorine

to obtain 1-log C*T credit for Giardia; 4-log C*T credit for viruses and maintain a distribution

system residual of 0.2 mg/L at the farthest customer tap. The facility is being upgraded to

conventional treatment with intermediate ozone followed by biological filtration followed by Ultraviolet

disinfection and secondary disinfection with chloramines. As shown in Table 1, the upgrade

adds a disinfection barrier for Cryptosporidium and dramatically reduces DBPs. DBP values for

the system after the change are based on bench scale data from simulated distribution system

DBP formation experiments. The upgrade is also anticipated to reduce customer complaints

from season taste and odor problems experienced by this water system due to algae.

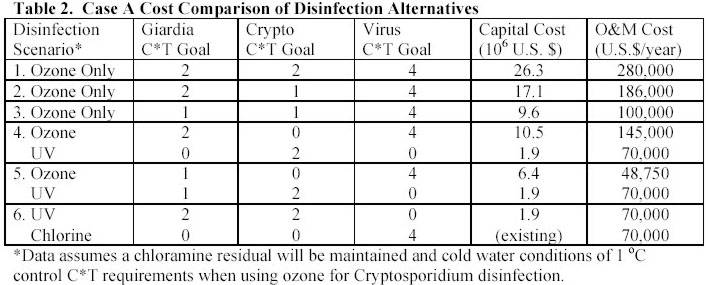

Cost estimates for the upgrade are shown in Table 2 and are calculated for a number of

disinfection scenarios (load sharing between ozone and Ultraviolet) that were considered. Option 5 was

ultimately selected since the optimum use ozone was determined to be for taste and odor control,

for viral disinfection credit and to provide some backup for Giardia disinfection to the Ultraviolet

system. Due to uncertainties with ozone C*T requirements for Cryptosporidium disinfection

credit in cold waters it was assumed that the ozone would have no credit. However, the ozone

system will provide some disinfection back-up to the Ultraviolet system for Cryptosporidium during

most of the year when operating temperatures are well above 5 0C. The overall capital cost

estimate for the multiple disinfectant barrier upgrade is $8.3 million with an annual operation and maintenance (O&M) cost estimate of $118,750. Clearly, the project benefits far outweigh

the costs of the upgrade.

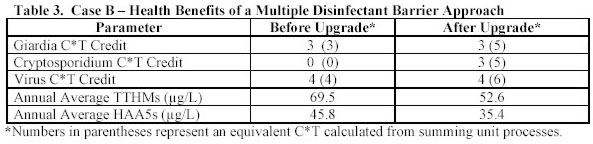

Case B Ė Unfiltered Drinking Water Supply with Ozone/Ultraviolet Disinfection and Chloramines

Case B involves a 300 MGD (47,320 m3/hr) unfiltered drinking water supply that had used

watershed protection practices and chlorine to obtain 3-log C*T credit for Giardia; 4-log C*T

credit for viruses and maintain a distribution system residual of 0.2 mg/L at the farthest customer

tap. The facility is being upgraded to additional watershed protection practices ozone followed

by Ultraviolet disinfection and secondary disinfection will remain chlorination. As shown in Table 3,

the upgrade adds a significant double disinfection barrier for Giardia and for Cryptosporidium

and reduces DBPs but not as much as in Case A since chlorine remains the secondary

disinfectant of choice in this system. DBP values for the system after the change are based on

bench scale data from simulated distribution system DBP formation experiments.

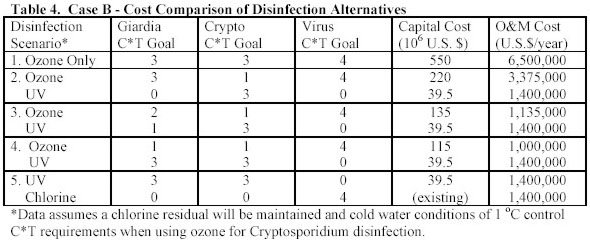

Cost estimates for the Case B upgrade are shown in Table 4 and are calculated for a number of

disinfection scenarios (load sharing between ozone and Ultraviolet) that were considered. Option 4 was

ultimately selected since the optimum use ozone was determined to be for taste and odor control,

for viral disinfection credit and to provide some backup for Giardia and Cryptosporidium

disinfection credit in cold waters it was assumed that the ozone would have no credit. The

overall capital cost estimate for the multiple disinfectant barrier upgrade is $154.5 million with an annual operation and maintenance (O&M) cost estimate of $2,400,000. The plant design flow

is large and relatively speaking the project benefits far outweigh the costs of the upgrade.

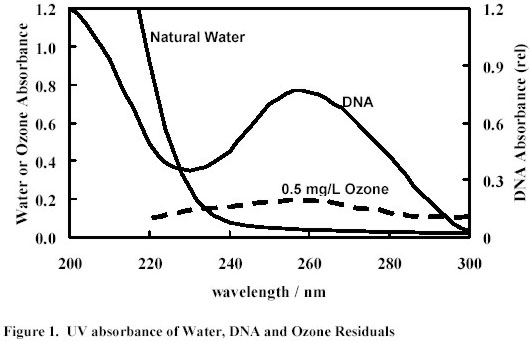

The Case B studies also examined the effects of ozone on the design of the Ultraviolet disinfection

system. Ozone prior to Ultraviolet disinfection can significantly improve the Ultraviolet transmittance (UVT)

of the water and UVT is a critical parameter for determining Ultraviolet disinfection system design and

operating costs. As shown in Figure 1, the Ultraviolet absorbance of a water sample can be affected by

the natural water components and the presence of an ozone residual. Ultraviolet absorbance of the

water in the same range where DNA absorbs Ultraviolet light can be considered analogous to a chlorine

or ozone demand of the water in terms of its ability to interfere with Ultraviolet disinfection processes.

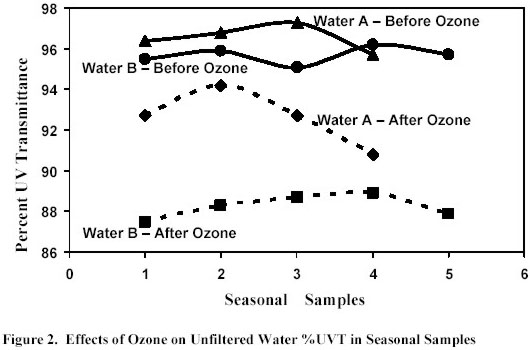

However, as shown in Figure 2 when natural water supplies are ozonated and there is no ozone

residual remaining then the overall Ultraviolet transmittance of the water is increased by as much as 8%

in the germicidal range and this will make Ultraviolet disinfection more cost effective to implement.

The benefits of ozonation on Ultraviolet disinfection design are site specific and must be evaluated on a case by case basis due to difference is water quality, differences is local disinfection design

objectives and differences in power costs. In most cases, the economic benefits of ozonation on

Ultraviolet disinfection design would not justify the capital and operating costs of implementing

ozonation. However, for many systems that either have ozone in place or that will install

ozonation for multiple benefits such as taste and odor control then the benefits of ozone prior to

Ultraviolet disinfection should be considered. Often it is prudent to design Ultraviolet disinfection systems for

a conservative Ultraviolet transmittance assuming that ozone will not be used but then to operate the Ultraviolet

disinfection systems at a reduced power level if ozonation is applied and the UVT has improved.

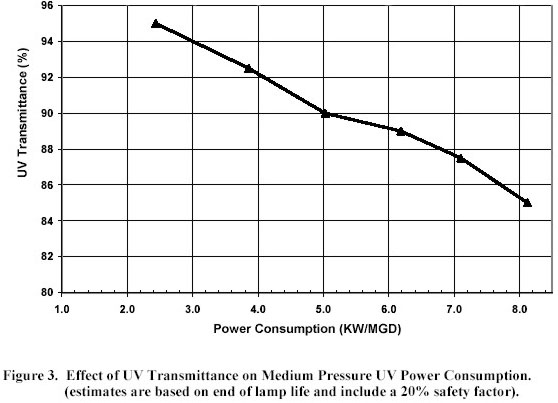

As shown in Figure 3, increased UVT can significantly reduce the power requirements for a

medium pressure Ultraviolet disinfection system delivering a validated Ultraviolet dose of 40 mJ/cm2 at the end

of lamp life.

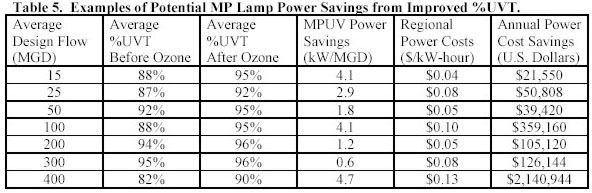

Table 5 shows the cost savings for a variety of system specific conditions that have been studied

by the authors in recent years. These data suggest that savings are significant especially if the

flows are large and the UVT prior to ozonation is relatively low. However, they also show that

the savings are site condition specific and if UVT of the water is high and/or the regional power

costs are low then this potential benefit of ozonation on reducing Ultraviolet power costs is negligible.

Case C - Conventional Treatment with Ultraviolet and Chlorine Disinfection and Chloramines

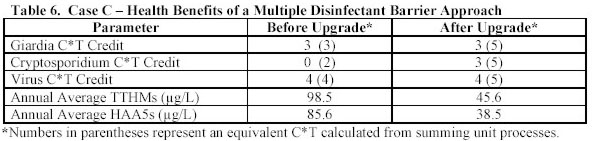

Case C involves a 50 MGD (7,887 m3/hr) conventional treatment facility that had used chlorine

to obtain 2-log C*T credit for Giardia; 4-log C*T credit for viruses and maintain a distribution

system residual of 0.2 mg/L at the farthest customer tap. The facility is being upgraded to conventional treatment with followed by Ultraviolet disinfection to achieve 3-log credit for Giardia and

Cryptosporidium and secondary disinfection with chlorine to achieve viral C*T and then

conversion to chloramines for distribution system protection. As shown in Table 6, the upgrade

adds a disinfection barrier for Cryptosporidium and dramatically reduces DBPs. DBP values for

the system after the change are based on bench scale data from simulated distribution system

DBP formation experiments.

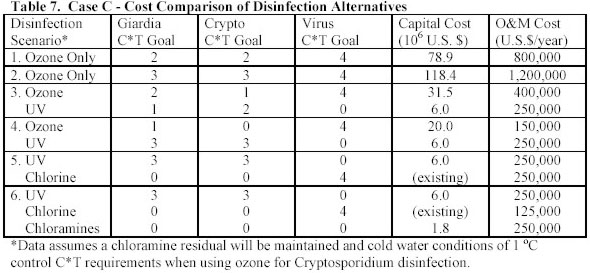

Cost estimates for the Case C upgrade are shown in Table 7 and are calculated for a number of

disinfection scenarios (load sharing between ozone and Ultraviolet) that were considered. Option 6 was

ultimately selected since ozone was not considered necessary nor desirable for this facility due to

costs and complexities of operation and conversion to chloramines to reduce DBPs was highly

desirable. The overall capital cost estimate for the multiple disinfectant barrier upgrade is $7.8

million with an annual operation and maintenance (O&M) cost estimate of $625,000. Clearly,

the project benefits far outweigh the costs of the upgrade for this 50 MGD (7,887 m3/hr) facility.

Conclusion and Recommendations

This paper has identified the changing political, economic and technical factors that influence

multiple barrier approach to waterborne disease protection that has been used in the U.S. for the

past century. A case is made here for a new paradigm which employs the use of multiple disinfectant barriers within the traditional multiple barrier approach. Using case studies the

paper has identified the health benefits of switching to a multiple disinfectant barrier approach as

well as some of the cost factors and comparisons that are needed. The potential benefits of using

ozone and Ultraviolet disinfection are also presented and are shown to be site specific. Clearly a

drinking water utility must carefully evaluate the pros and cons of the wide variety of multiple

disinfectant barrier options that are presently available to them. The final decision needs to be

site specific and should consider as a minimum: the desired pathogen inactivation; DBP

formation and control; and the capital and O&M costs of each option.

Acknowledgements

This paper would not have been possible without the support both financial and technical as well

as the knowledge provided to our research group over the past 12 years by numerous sponsors

including AwwaRF, USEPA, EPRI, WERF, NHDES, NOAA, CH2M Hill, Black & Veatch,

Dufresne and Henry, FS&T, Wright-Pierce and Carollo Engineers. In addition, we are indebted

to the dozens of drinking water utilities and their personnel who have taught us so many practical

lessons about disinfection processes and often let us use their water treatment facilities as our

laboratory.

James P. Malley, Jr.; Steven E. Farabaugh; David R. Gaithuma and Nicola A. Ballester

Ultraviolet Shadow Force Research Laboratory

University of New Hampshire, Environmental Technology Bldg. Rm. 230 Durham, NH, 03824, USA

|