Station for Disinfection of Potable Water and Clarified Sewage with Capacity of

24000

m3/day (1000

m3/h).

Description of station for disinfecting sewage.

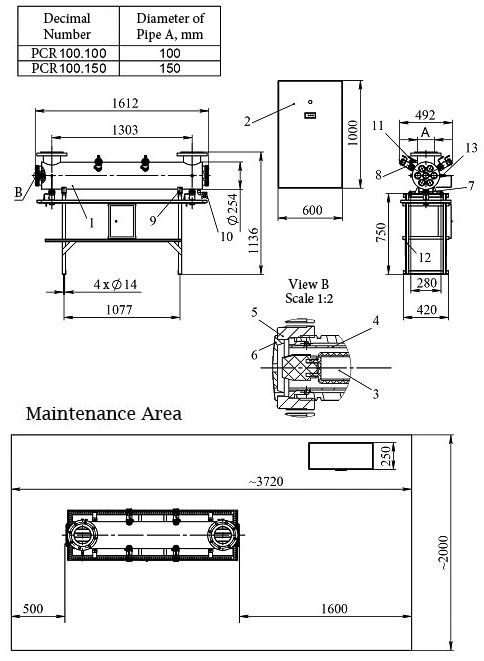

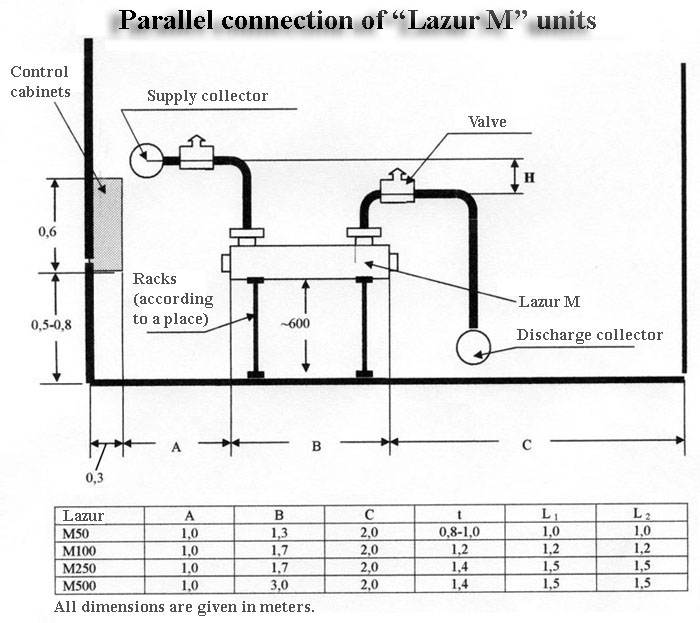

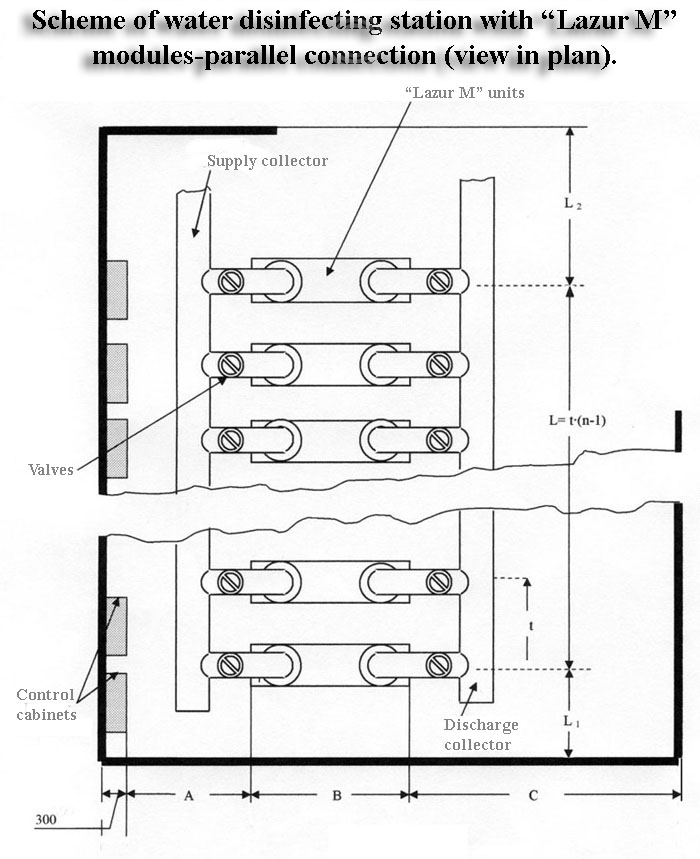

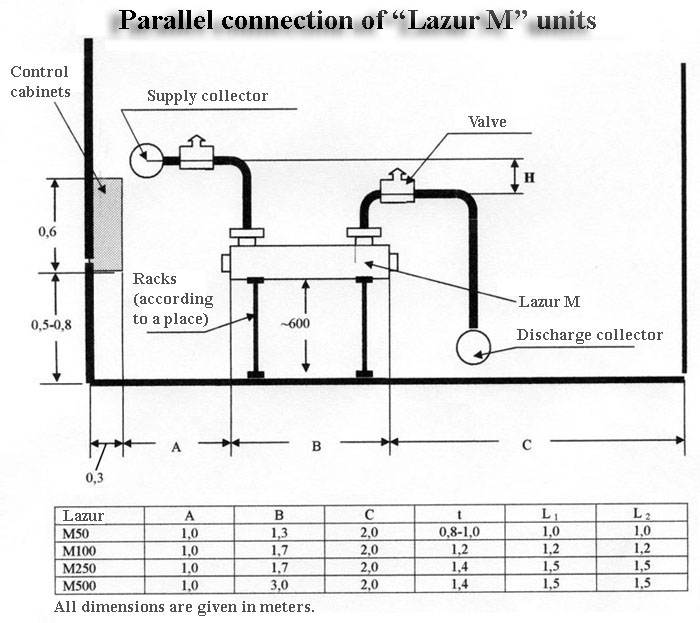

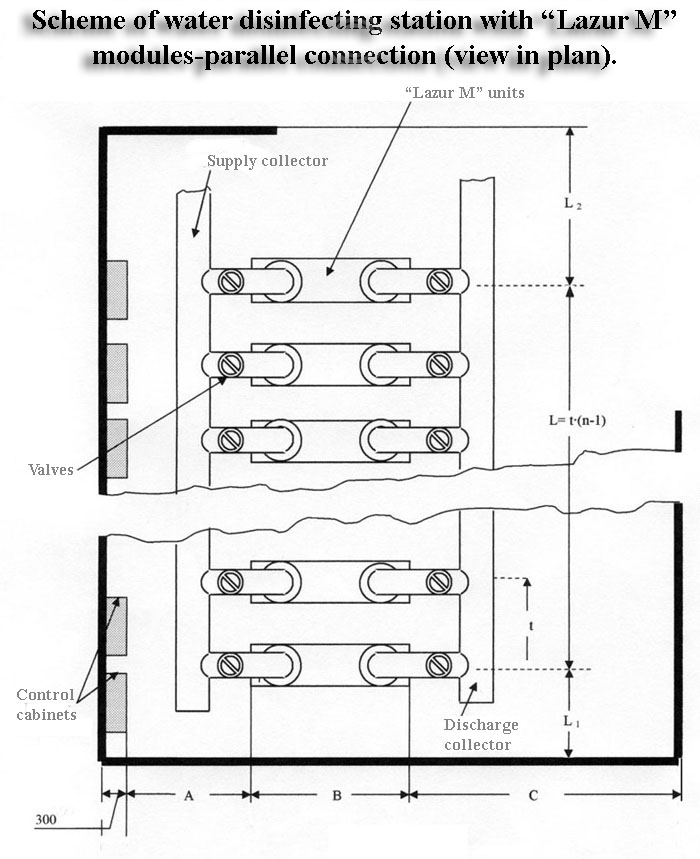

The station is based on the use of “Lazur M-100” units (Fig. 1) of 100 m3/h capacity. In the case of parallel connection of the modules (Figs. 2,3), the station is composed of ten working units and one reserve unit.

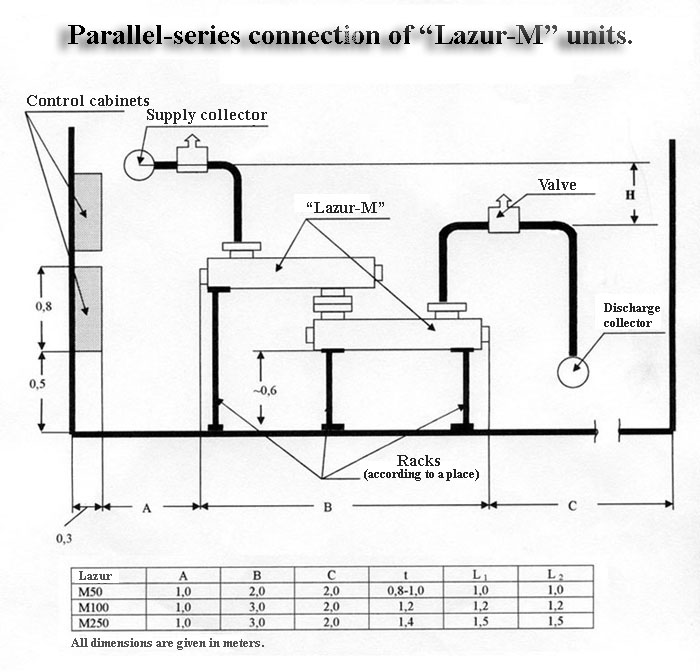

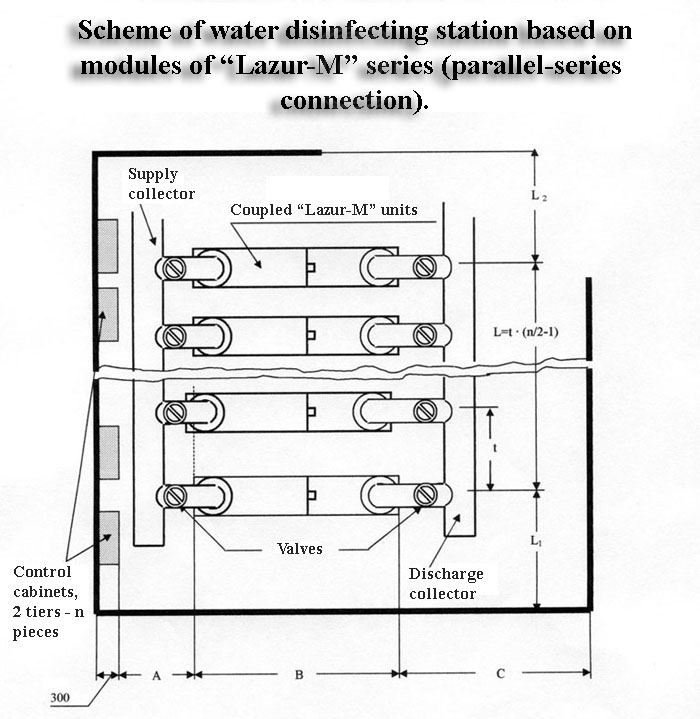

When parallel-series connection of modules is employed, (Figs. 4,5), the station is built up of 5 working chains and one reserve chain, each chain being composed of two series coupled modules.

The inlet and outlet of each module (for the first configuration of the station) of each chain (in the case of parallel connection) are separated from the corresponding collectors by pipeline valves. These valves serve for leveling the flow rates passing through the branches and possibility of cutting off the unit or the chain for performing the preventive maintenance.

The power supply cabinets are mounted nearby each section on a wall or in a rack. The overall dimensions of the power supply cabinet of one unit are 800 x 600 x 300 mm.

The cabinets are raised over the floor level so as to allow convenient mounting/dismantling of the gas-discharge lamps in the modules. The distance between the chains must be ~ 1.2 m. The lower module in the chain must be raised to a height over a floor not less than 50 cm.

The overall area occupied by the station together with the service zone for the series and parallel-series connection must be ~75 m2 and ~65 ì2, respectively. The total power consumption is 30 kW.

Description of “Lazur M-100” unit.

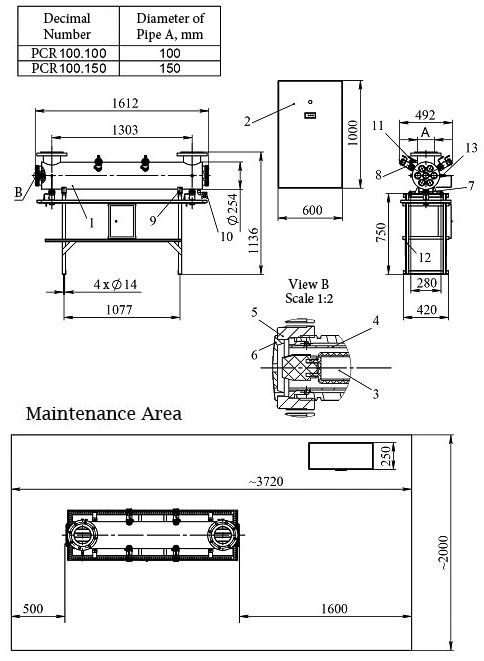

“Lazur M-100” unit represents the cylindrical design made of stainless steel (Fig. 1, pos. 1), wherein the ultraviolet radiators enclosed in protective quartz casings (Fig. 1, pos. 2) and ultrasonic transmitters are arranged. The volume of the unit is 70l, and the weight is 35 kg.

The ultraviolet radiators are essentially the low-pressure mercury vapor lamps provided with the bulb made of synthetic quartz (“Suprasil”). The length of the lamp is 1500 mm. Each lamp consumes a power of 325 W from the net (220 V, 50 – 60 Hz). The lamp radiates UV light (100 W) in the spectral region of UV – Ñ band (254 nm). The flux density of the bactericidal radiation at a surface of the protective glass (“Suprasil”) is not less than 80 mW/cm2. The service life of the lamp is not less than 12,000 h of continuous burning. The lamps of NNI 300 type have longer service life (16,000 h). The lamps are supplied with power by means of the HF (44 kHz) transformer. Ìàãàçèí ïíåâìàòèêè: ñíàéïåðñêàÿ âèíòîâêà äëÿ ñòðàéêáîëà. Âèíòîâêè äëÿ ñòðàéêáîëà.. ñïàéñ â ìîñêâå

Each module makes use of seven (7) lamps.

Six (6) ultrasonic (US) transmitters (Fig. 1, pos. 3) are arranged symmetrically on the side surface of the enclosure. Each US transmitter emits 100 W at a frequency of 25 kHz. The service life of the US transmitter is not less 10,000 h.

The total consumed power is 3.0 kW.

Thus, when a liquid passes through the module, it is subjected to the simultaneous combined action of ultraviolet irradiation (with a flux density of over 40 mW x s/cm2) and ultrasound (with a power density of more than 2 W/cm2.

Under the action of these factors, in the water under treatment strong cavitation and deep oxidative processes take place. They proceed due to the effect of ultraviolet and ozone (O3) resulting from UV irradiation in vapor-gas bubbles (with a mean diameter of less than 0.1 mm) uniformly spread over the whole operative volume of the module. During this treatment process, the other strong oxidants (H2O2, OH, etc.) also form.

This technology allows the treatment of turbid liquids (with a level of transparency to 50%) as well as of the liquids containing appreciable amounts of suspended particles (with a content of up to 10 mg/l) and the concentrations of Fecal Coliforms up to 1,000,000 units/l. Moreover, the application of ultrasound does not allow particles, which are present in the liquid to form a sediment on the protective glass and walls of the working chamber thus increasing the operation effectiveness. This makes unnecessary the cleaning of the surfaces in contrast to the conventional ultraviolet water treatment technology.

The described above unit is significantly more affective (by a factor from 100 to 1000) as compared with the conventional ultraviolet disinfecting systems with analogous power consumption and capacity of the UV-3000 type produced by the Trojan Company.

The series coupling of two “Lazur M-100” units appreciably increases the reliability and still more enhances its disinfecting characteristics with respect to destruction of spore-forming (with a content of up to 1,000,000 units/l), virus forms (with a content of up to 100,000 units/l), fungous microorganisms ( with a content of up to 10,000 units/l), molds ( with a content of up to 1000 units/l), and protozoa ( with a content of up to 1000 units/l).

To provide the necessary capacity of the station in the mode of the gravity flow, the total drop in the height from the outlet of biological (or any other) purification system to the outlet of the system in point must be from 4 to 6 m.

All the modules are provided with necessary devices controlling their operation. The levels of ultraviolet radiation and the power of ultrasonic transmitters are permanently monitored. The power supply blocks are equipped with connectors for linking-up to the total control system. Fig . 1

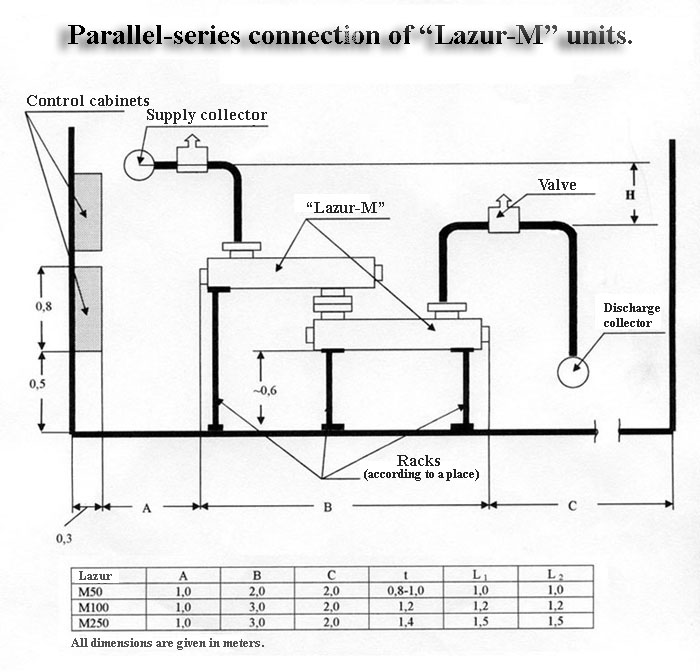

Fig. 2

Fig. 3

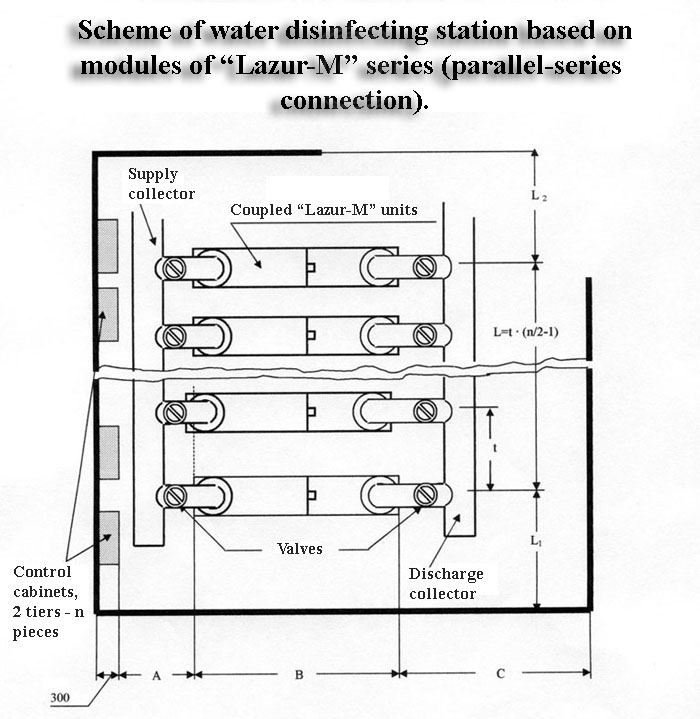

Fig. 4

Fig. 5

|